From battery security to powertrain Validation – fixing immediately’s testing challenges with scalable, high-accuracy DAQ options

EV testing is evolving—are your measurement programs maintaining?

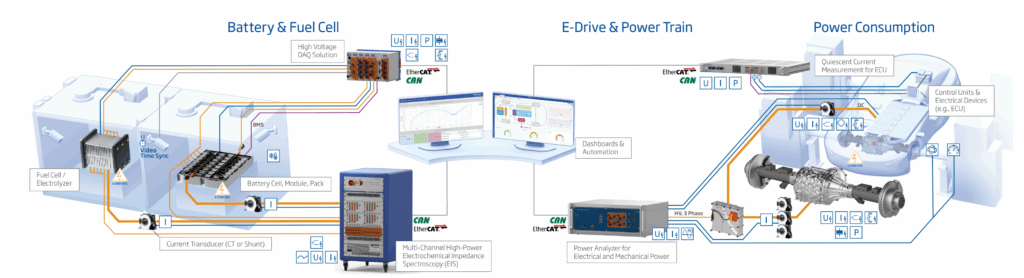

The shift to electrical mobility is pushing the boundaries of battery efficiency, powertrain effectivity, and end-of-line validation. Engineers and producers are beneath rising stress to enhance security, improve power effectivity, and scale back manufacturing prices, all whereas coping with larger voltages, advanced power storage programs, and more and more stringent testing necessities.

These challenges demand a brand new technology of check and measurement options—ones that transcend normal DAQ programs to ship real-time insights, seamless integration, and industry-leading accuracy throughout a spread of check environments.

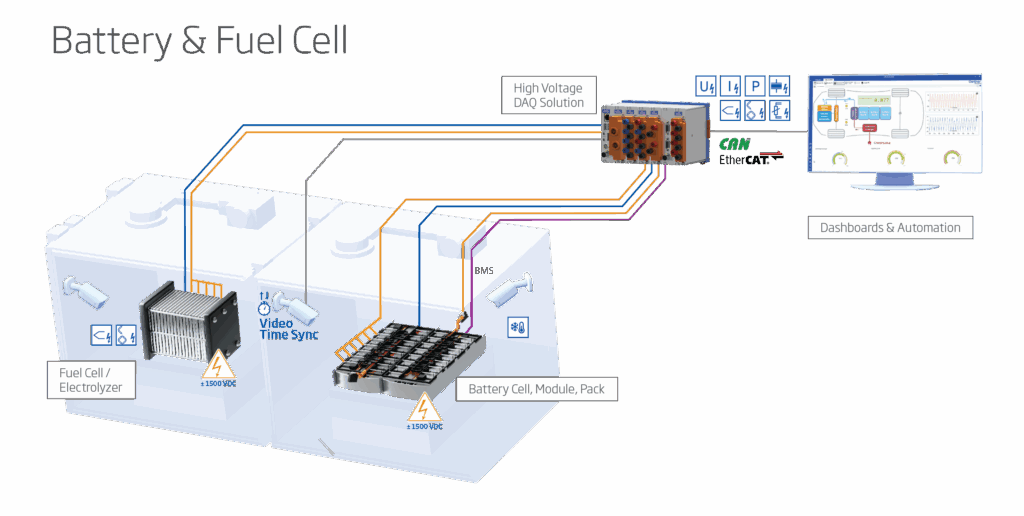

Battery abuse testing wants extra than simply information—it wants visible proof

Battery failures can occur in milliseconds throughout penetration or short-circuit testing. Whether or not it’s a thermal runaway occasion or mechanical deformation, figuring out the precise location requires extra than simply numerical information—it requires real-time, synchronized measurements with high-speed information acquisition.

HV information acquisition options

HV information acquisition options

Our high-speed HV DAQ sy stems combine seamlessly with video recording, making certain that each body is time-synchronized with electrical, thermal, and mechanical measurements on potentials as much as 1500 VDC. With best-in-class noise efficiency and sampling charges of as much as 4 MHz, engineers can seize vital occasions with absolute precision. The system operates remotely and totally synchronized, making certain that even advanced multi-channel check setups stay correct and dependable beneath excessive testing circumstances. Highly effective information archiving and clever compression enable for long-duration testing whereas sustaining high-resolution information integrity.

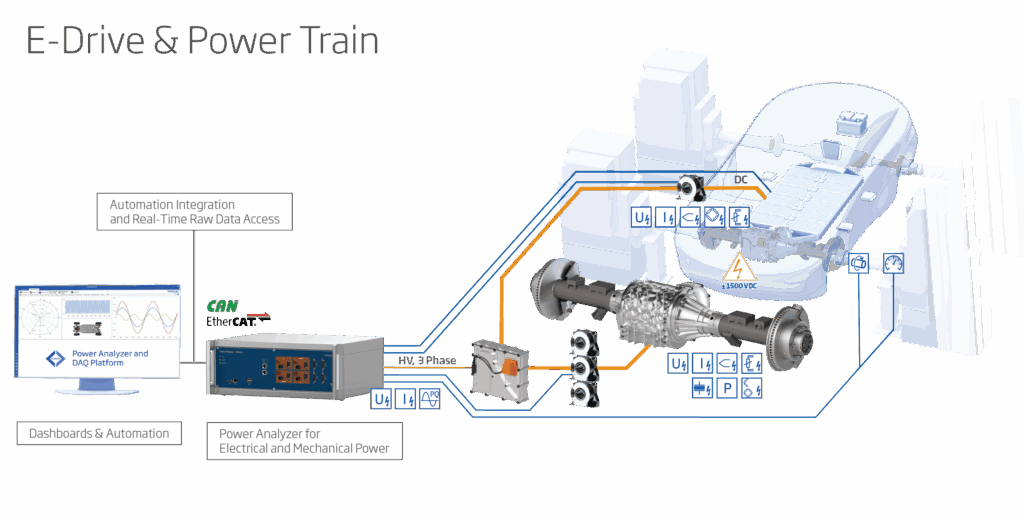

Powertrain effectivity is barely pretty much as good as the info behind it

As expertise advances, EV powertrains function at larger voltages and sooner switching frequencies. Conventional energy analyzers wrestle to ship correct measurements with adequate signal-to-noise ratio and low distortion throughout inverters, motors, and batteries, resulting in missed effectivity optimizations.

Energy analyzer for seamless check mattress integration

Energy analyzer for seamless check mattress integration

Our GPA100 Energy Analyzer delivers real-time electrical and mechanical energy evaluation with ultra-low noise flooring efficiency and a 4 MHz sampling fee per channel—the most effective in its class. That includes clever information compression and high-speed EtherCAT integration, it supplies triggered information logging and direct entry to uncooked values, making certain instantaneous insights for optimizing powertrain effectivity. With open interfaces supporting varied protocols, the GPA100 is designed for seamless integration into check benches and end-of-line manufacturing environments. Its intuitive software program and compatibility throughout a number of working programs make it a flexible answer for R&D and large-scale validation.

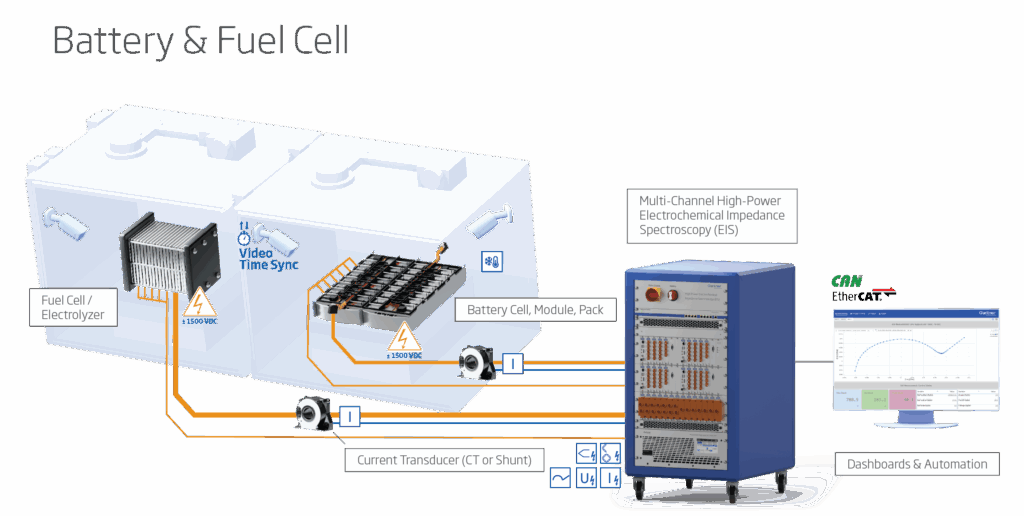

EIS at each degree – cell, module, and pack

Battery expertise isn’t simply evolving—it’s diversifying. From solid-state cells to high-capacity packs, every new design brings distinctive challenges in voltage monitoring, impedance evaluation, and thermal conduct. Many DAQ programs wrestle to scale, forcing engineers to make use of a number of platforms for various testing levels, creating integration complications and information inconsistencies.

The Gantner EIS system

The Gantner EIS system

Our EIS answer supplies a single, scalable platform that may adapt to battery testing at each degree—from particular person cells to full packs. With distant and synchronized measurement capabilities, engineers can monitor battery ageing and efficiency degradation in real-time, even beneath full cost or discharge circumstances. This method is totally synchronized with further temperature, pressure, and voltage measurements, making certain a complete evaluation of battery conduct. Constructed with highly effective information archiving and clever compression, it permits long-term monitoring of battery traits, supporting predictive upkeep and degradation modeling. The system’s open interfaces and help for a number of communication protocols guarantee straightforward integration with third-party {hardware} and software program.

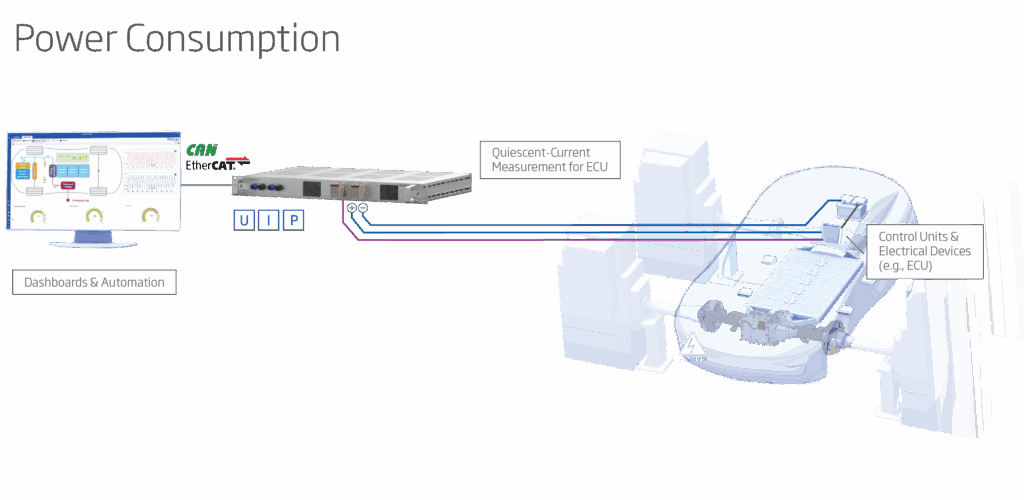

Present measurement – detecting the hidden battery drain

Present measurement – detecting the hidden battery drain

EV batteries don’t simply lose energy on the highway—they lose power when parked. Fashionable electrical automobiles depend on a whole bunch of ECUs, sensors, and digital subsystems that proceed drawing energy in standby mode. Over time, these low-level energy drains scale back battery longevity, shorten automobile vary, and enhance guarantee considerations for automakers. Many conventional measurement programs lack the decision and real-time capabilities wanted to detect energy consumption within the microampere vary, making it tough for engineers to determine and eradicate pointless losses.

Options for breadboard testing

Our Quiescent Present Measurement System delivers ultra-low present detection with microampere (µA) precision, enabling engineers to profile standby energy consumption and optimize automobile electronics precisely. The system runs in real-time on any OS, making certain seamless integration into each lab-scale testing and large-scale manufacturing environments. Designed for totally automated end-of-line testing, it options open interfaces and clever information compression, permitting engineers to investigate long-term developments whereas minimizing storage necessities. The synchronized, distant operation functionality ensures excessive accuracy even in distributed check setups, serving to producers meet stringent effectivity and compliance targets.

Future-proof your EV testing with Gantner Devices

Future-proof your EV testing with Gantner Devices

Testing necessities are getting harder, and measurement programs shouldn’t be the weak hyperlink. Our modular DAQ options are designed to seize each vital information level with out compromise, providing scalable architectures, distant synchronization, and seamless integration with present check environments. Whether or not you’re pushing the boundaries of battery sturdiness, fine-tuning powertrain effectivity, or making certain flawless manufacturing high quality, Gantner Devices supplies the instruments and expertise to maintain you forward.

With intuitive software program interfaces, real-time analytics, and highly effective information administration, our programs simplify the complexity of EV testing whereas delivering unmatched accuracy, decision, and adaptability. Our open interfaces and help for varied protocols be sure that Gantner options combine simply into your present infrastructure, holding your check programs future-ready and adaptable to new testing requirements and methodologies.